FRP Lining in Pickling Tank

Price 500 INR/ Square Meter

MOQ : 1 Square Meter

FRP Lining in Pickling Tank Specification

- Base Material

- Mild Steel / Concrete (as per tank construction)

- Repairability

- Easily repairable and patchable onsite

- Lining Thickness

- 3 mm to 5 mm (customizable)

- Surface Finish

- Glossy / Smooth Finish

- Tolerance

- ±0.5 mm in thickness

- Product Name

- FRP Lining in Pickling Tank

- Coating System

- Consists of primer coat, FRP layers, and top coat

- Color

- Green / Dark Grey (standard, customizable available)

- Water Absorption

- <0.2%

- Compressive Strength

- 180 - 200 MPa

- Application

- Anti-corrosive lining for pickling tanks in chemical processing industries

- Chemical Resistance

- Excellent resistance to acids, alkalis, and solvents

- Customization

- Thickness, resin grade, and color as per requirement

- Flexural Strength

- 250 - 300 MPa

- UV Stability

- Available on request for outdoor installations

- Standards Followed

- IS 6746, ASTM D256

- Adhesion Strength

- Good bonding with metal and concrete substrates

- Lining Material

- FRP (Fiber Reinforced Plastic)

- Temperature Resistance

- Up to 100°C

- Installation Method

- Hand lay-up / Spray-up onsite

- Service Life

- 10-15 Years (Depending on usage and maintenance)

FRP Lining in Pickling Tank Trade Information

- Minimum Order Quantity

- 1 Square Meter

- Supply Ability

- 5000 Square Meters Per Month

- Delivery Time

- 10 Days

About FRP Lining in Pickling Tank

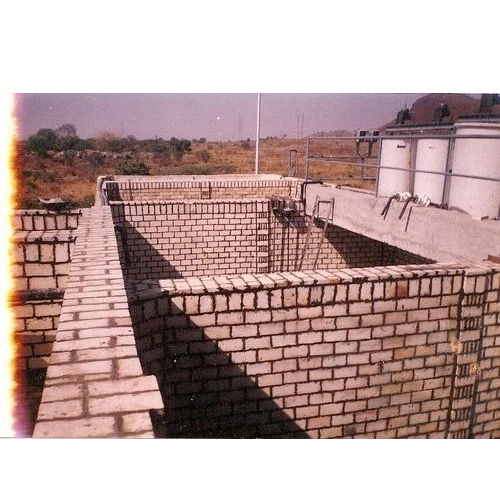

FRP Lining in Pickling Tank is a monumental solution for chemical processing industries, offering dazzling resistance against corrosive environments. Manufactured by leading distributors, exporters, and service providers in India, this in-demand product comes at a special rate, making it a true bargain for quality and longevity. The high-performance FRP lining boasts a compressive strength of 180200 MPa, flexural strength of 250300 MPa, and remarkable chemical resistance. Customizable in thickness, resin grade, and color, it is ideal for metal and concrete tanks, ensuring decades of protection and easy onsite repairs.

Applications of FRP Lining in Pickling Tank

FRP Lining in Pickling Tanks is widely applied in chemical processing plants, offering anti-corrosive protection for both mild steel and concrete structures. Its primary use is to extend the longevity of pickling tanks, especially in industries handling acids, alkalis, or solvents. The solution is further remarked for its durability in electroplating, galvanizing, and metal-finishing units, making it essential to preserving equipment while maintaining operational safety.

FRP Lining Delivery and Order Processing

Our transport services ensure timely delivery of FRP Lining in Pickling Tank after efficient order processing. Upon receipt of a confirmed purchase order, products are dispatched from Indias primary FOB ports, with delivery timelines shared upfront. We also offer samples so you can substantiate product quality before large-scale purchase. Experience smooth logistics, competitive special rates, and professional support with every transaction, all orchestrated to meet your operational deadlines.

Applications of FRP Lining in Pickling Tank

FRP Lining in Pickling Tanks is widely applied in chemical processing plants, offering anti-corrosive protection for both mild steel and concrete structures. Its primary use is to extend the longevity of pickling tanks, especially in industries handling acids, alkalis, or solvents. The solution is further remarked for its durability in electroplating, galvanizing, and metal-finishing units, making it essential to preserving equipment while maintaining operational safety.

FRP Lining Delivery and Order Processing

Our transport services ensure timely delivery of FRP Lining in Pickling Tank after efficient order processing. Upon receipt of a confirmed purchase order, products are dispatched from Indias primary FOB ports, with delivery timelines shared upfront. We also offer samples so you can substantiate product quality before large-scale purchase. Experience smooth logistics, competitive special rates, and professional support with every transaction, all orchestrated to meet your operational deadlines.

FAQs of FRP Lining in Pickling Tank:

Q: How does FRP Lining in Pickling Tank enhance anti-corrosive protection?

A: FRP Lining provides excellent resistance to acids, alkalis, and solvents due to its advanced fiber-reinforced plastic composition, effectively shielding pickling tanks from corrosion and extending service life.Q: What is the process of installing FRP Lining in pickling tanks?

A: Installation involves onsite hand lay-up or spray-up methods, starting with a primer coat, followed by FRP layers, and finished with a top coat to ensure comprehensive protection and smooth finishing.Q: When should FRP Lining be used in chemical processing plants?

A: FRP Lining is best employed in pickling tanks that encounter aggressive chemical reactions, frequent exposure to corrosive substances, or require a durable, long-lasting protective layer.Q: Where is FRP Lining typically applied within industrial settings?

A: FRP Lining is commonly used in the pickling tanks of chemical processing plants, electroplating facilities, and metal-finishing units, particularly where anti-corrosive performance is essential.Q: What benefits can users expect from customizing FRP Lining specifications?

A: Customizing thickness, resin grade, and color allows users to match the lining precisely with their operational needs, improving chemical resistance, temperature tolerance, and design suitability for various environments.Q: How long does the FRP Lining typically last once installed?

A: Depending on usage and maintenance, FRP Lining offers a remarkable service life of 10 to 15 years, providing enduring protection for industrial tanks.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS